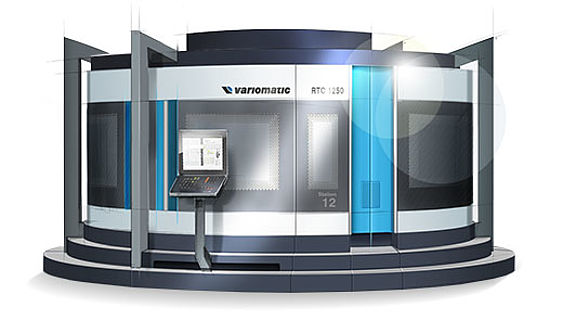

Unsere Rundtaktmaschinen für Ihre Serienfertigung

Erfahrung macht uns zu dem, was wir heute sind: Variomatic steht für jahrzehntelange Maschinenbautradition. Mit unseren Rundtaktmaschinen zur Massenfertigung setzen wir die Visionen der Gründerjahre fort und entwickeln uns stetig weiter. Modular, übersichtlich und platzsparend entsprechen unsere Entwicklungen neuesten technologischen Standards. Jede unserer Maschinen ist dabei ein echtes Unikat und passt sich individuell an Ihre Bedürfnisse und Gegebenheiten an. Mit unseren Werkzeugmaschinen optimieren Sie Ihre Produktionsprozesse und setzen Ihre Ressourcen effizient ein.

Produkte

Service & Support

Ersatzteil- Service

Komponenten

Technische Unterstützung

Überholung

Schnell, persönlich und umfassend – das zeichnet unseren Variomatic-Maschinenservice aus. Unsere Experten stehen Ihnen mit Know-how gern zur Seite: Wir bieten Ihnen kompetenten und unkomplizierten Support, Wartung und fachmännische Beratung – vor und nach dem Kauf.

REFERENZEN

Unser Ziel sind zufriedene Kunden. Deren größtes Lob: viele unserer Rundtaktmaschinen sind nicht allein im Einsatz. Ein Großteil unserer Kunden hat sich für mehrere unserer Bearbeitungszentren zur Massenfertigung entschieden. Egal ob Ersatzteile für Maschinen mit einer über vierzigjährigen Einsatzdauer oder Konzentration auf neueste Technikstandards und Industrie 4.0 – wir sind für unsere Kunden da und setzen mit Tradition, Ingenieurskunst und modernen Maschinen auf individuelle Lösungen.

Sie wollen mehr zu unseren Referenzen erfahren? Sprechen Sie uns an.

Ihre Karriere bei VARIOMATIC

Es gibt viele gute Gründe bei Variomatic zu arbeiten: Profitieren Sie von der Erfahrung und Beständigkeit eines erfolgreichen mittelständischen Unternehmens. Bei uns können Sie sich zukunftsorientiert und kontinuierlich weiterentwickeln und Verantwortung übernehmen. Wir bieten Ihnen ein familiäres Arbeitsumfeld, in dem Loyalität und Offenheit im Umgang miteinander großgeschrieben werden. Gemeinsam realisieren wir individuelle Kundenwünsche und schaffen Unikate: Wir freuen uns auf Ihre Impulse für die Zukunft!