PRECISE AND EFFICIENT MASS PRODUCTION

The economic potential of state-of-the-art rotary transfer machines

Modern rotary transfer machines are the perfect solution for all manufacturers of medium-sized, large and mass series of aluminium, steel, brass and other materials with more than one million parts per year. The machining steps are arranged circularly around a horizontal indexing table and are performed simultaneously so that a finished workpiece is ejected and a new blank fed in with every cycle. The configuration of the work processes such as milling, drilling, piercing, turning, tapping or broaching is adapted flexibly to your respective requirements.

There are very good reasons to choose machine tools from Variomatic:

- Series production with high precision and productivity

- Versatile use of the machine tools

- The modular structure makes your investment flexible

- High efficiency with regard to time, personnel, maintenance and space requirements

- We are a mechanical engineering company with experience and tradition

- Every machine is unique, adapted to the technologies and conditions on site

Rotary transfer production is well worth it!

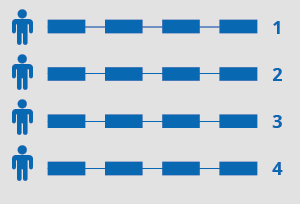

Multi-machine processing

- More personnel required

- Higher investment expenses

- More space required

- Manual retooling

- Varying qualities

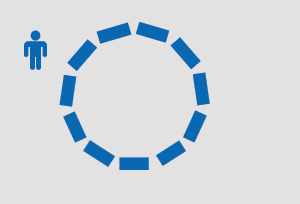

Rotary transfer machining

- Less personnel required

- One clamping setting for all work processes

- High process reliability

- Quality and precision for all production steps

- Optimal productivity without retooling times

Conventional machining versus rotary transfer machining

Conventional machining

- 4 people

- 4 different levels of quality

- 4 interfaces

- 4 times more space required

Rotary transfer machining

- Faster

- More accurate

- More productive

- Reliable

What are the minimum quantities and complexity that make the use of a rotary transfer machine worthwhile?

Machining

> 4 tools

Annual requirement

> 600,000

workpieces

Workpiece size

∅ up to 80 mm

Workpiece size

Edge length

up to 100 mm

Application examples

Rotary transfer machines from Variomatic are used in many different sectors of industry. Here is a just a selection of the branches in which these all-rounders are used:

Our machine tools offer the optimal prerequisites for use in the automotive branch, where primarily workpieces made of steel and aluminium alloys are machined. This is the ideal area of application for the Variomatic RTC. This machine series is used to manufacture parts, for example, for the engine, body, safety and fuel supply as well as for the gearbox and chassis.

The Variomatic T3i, on the other hand, is a good choice for smaller parts in the automotive branch.

The Variomatic T3i is at home in the electrical and electronics industry. This branch of industry mainly processes copper and aluminium materials and their alloys, right through to new lead-free brass types, to produce plugs, sockets, terminals, sleeves, contacts, special screws, special nuts, connection parts and much more.

The Variomatic T3i meets the requirements demanded and required by manufacturers for most applications for the production of lock casings, lock cores, lock cylinders, keys, couplings and bolts. The use of Variomatic RTC increases the number of applications considerably, especially for the production of larger parts. Thanks to the full-CNC equipment, the RTC can be programmed on all machining stations and is therefore even more flexible.

The Variomatic T3i meets the requirements demanded and required by manufacturers for most applications for the production of lock casings, lock cores, lock cylinders, keys, couplings and bolts. The use of Variomatic RTC increases the number of applications considerably, especially for the production of larger parts. Thanks to the full-CNC equipment, the RTC can be programmed on all machining stations and is therefore even more flexible.

Naturally, the branches named above do not cover the full range of applications of our machines. Numerous other workpieces can be manufactured and machined on Variomatic rotary transfer machines in addition to these parts. The crucial factors for compatibility are the size of the part, the scope of machining and the quantity. Please contact us – we will be happy to work with you to test the use of our machines for your specific requirements.