Excellent features of the Variomatic T3i

- Significant expansion of the production range

- Reorganisation of the machine periphery

- Flexible and fast retooling

- Maximum individualisation

- Modular configurability

- Horizontal and vertical CNC machining unit

- Optimised for internal coolant supply (ICS)

- Production of complex contours

- Modern, ergonomic industrial design

Product information

Cleverly refined

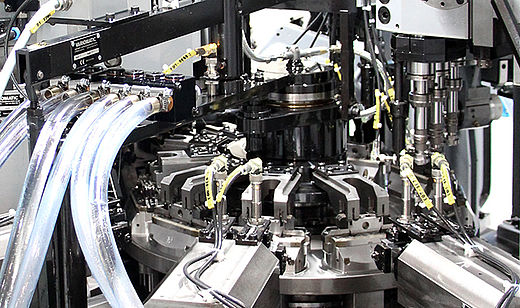

The Variomatic T3i is a long-lasting, reliable machine tool for efficient large series and mass production, which can be converted and changed modularly with little effort. It is based on assemblies that have been tested and optimised for decades and raises the expertise of its predecessor, the T3, to new levels.

The combination of consistent further development and newly developed assemblies makes the Variomatic T3i a highly efficient rotary transfer machine for the production of large quantities. With a production rate of up to 100 million workpieces per year, the strength of the T3i lies in its reliable service life.

Designed for high demands

The T3i was designed in accordance with the visual requirements of industrial designers. The clearly arranged environment with intelligent guidance creates a comfortable work place for the operator in accordance with the latest ergonomic standards. The improved accessibility for the user is evidence of the new quality of the Variomatic T3i as a work place.

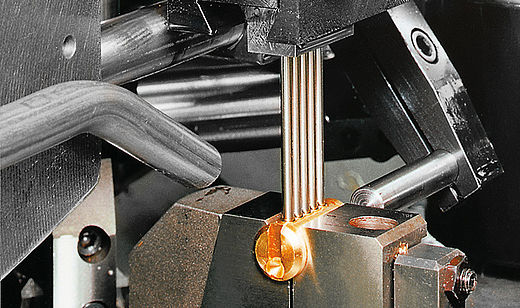

Better surface qualities are achieved by using tools with an internal coolant supply (ICS). The T3i provides convincingly higher performance than the predecessor models when it comes to machining steel, aluminium, lead-free brass and similar materials.

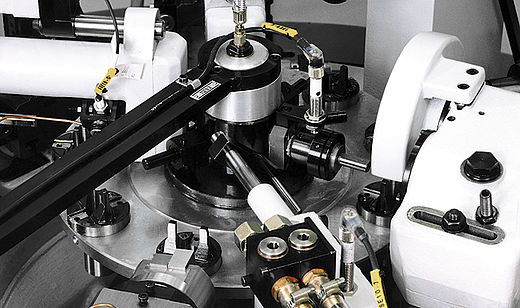

Consistently flexible

The production of more demanding workpieces with complex contours is possible thanks to the optional CNC-controlled machining with flexible, easily correctable or modifiable movements. The excellent compatibility of the individual assemblies allows more-versatile machining concepts and an even wider production range. The new T3i expands your parts portfolio and gives you the flexibility to respond quickly to changing circumstances without complications.

Performance characteristics

Control system

PLC Siemens | Simatic S7 | Sinumerik 840D sl

Drive

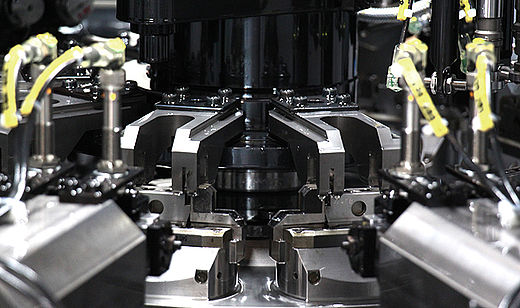

Rotary transfer table: mechanically cam-controlled

Feed units: mechanically cam-controlled | hydraulic | electro-mechanical

Internal coolant supply

Yes

Division | Number of workpiece carriers

T3-9i: 9

| T3-11i: 11

Clamping chuck design options

Fixed or 360° swivel-mounted

Workpiece sizes

Mainly smaller workpieces up to Ø 20 mm, width/height up to 30 mm, length up to 60 mm in brass, aluminium and steel Realisation of larger parts depending on machining parameters (performance and speed)

Workpiece clamping

Mechanical or hydraulic (single and multiple clamping possible)

Performance

3 – 100 million parts/year

Application examples T3i

Naturally, this does not cover the full application range of the Variomatic T3i. Numerous other workpieces can be manufactured and machined on Variomatic rotary transfer machines in addition to these parts. The crucial factors for compatibility are the size of the part, the scope of machining and the quantity. Please contact us – we will be happy to work with you to test the use of our machines for your specific requirements.

Downloads

-

Product brochure 601 KB

-

Technical specifications 73 KB

-

Image brochure 2 MB

Your point of contact

Mario Köhler

sales(at)variomatic.de

+49 371 84246-27