Excellent features of the Variomatic RTC

- Fast retooling

- CNC-controlled units

- High machining and repetitive accuracy

- Compact design

- Modular, straightforward machine periphery

- Long life under demanding production conditions

- Modern, ergonomic industrial design

Product information

Equipped for versatility

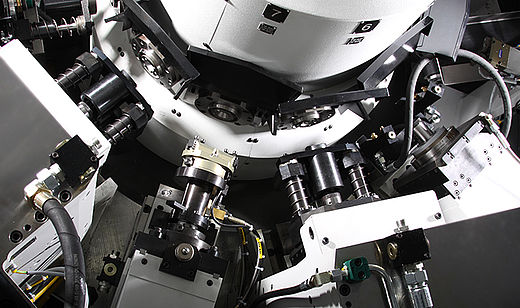

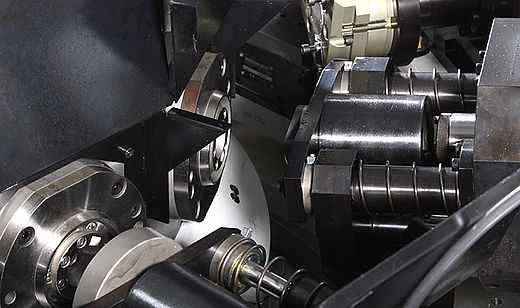

The Variomatic RTC is a perfect example of the flexibility and efficiency of rotary transfer machines. Fast retooling times, modular structure and CNC control in all units make it an indispensable companion – wherever medium-sized and large series are produced. The number of stations can be selected between six and sixteen. The machining units for this are available in different sizes and can be replaced according to the modular principle. Rugged, modular, clearly arranged: the transparent structure of the RTC demonstrates its advantages in daily performance. The system works reliably and economically in day-to-day production.

Excellent possibilities

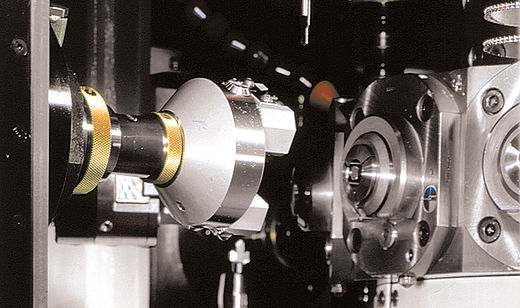

The flexibility of the Variomatic RTC comes not only from its clearly structured arrangement and the consistent CNC control but also from several special features. The workpieces can be machined on five sides in one clamping setting. This is also possible on six sides with automatic re-clamping. The Variomatic RTC enables simultaneous horizontal and vertical machining on one station. Different workpieces and material cross-sections can be machined by variable clamping principles and special clamping devices. You can even produce more than one finished part with every machine cycle by means of multiple clamping in one chuck.

Open for all directions

All machining units can work in vertical, horizontal and angled arrangement. Setting and adjustment in three axes is no problem thanks to the simple adjusting elements and good accessibility. The RTC has also been given a modern facelift. Experienced industrial designers have optimised the appearance of the flexible all-rounder. Extend your range of performance and be more flexible with the Variomatic RTC.

Performance characteristics

Control system

Sinumerik 840D sl

Drive

Rotary transfer table: electro-mechanical

Feed units: electro-mechanical/hydraulic

Internal coolant supply

Yes

Machine series

RTC500 / RTC630 / RTC900 / RTC1250

Division / Number of workpiece carriers

6 – 16

Clamping chuck design options

Fixed or 360° swivel-mounted

Workpiece sizes

Workpieces up to Ø 80 mm and W/H/L 100 mm in the form of bar material, forged and die-cast parts as well as pre-machined workpieces of brass, aluminium and steel, etc.

Workpiece clamping

Mechanical or hydraulic (single and multiple clamping possible)

Performance

0.5 – 8 million parts/year

Application examples RTC

Naturally, this does not cover the full application range of the Variomatic RTC. Numerous other workpieces can be manufactured and machined on Variomatic rotary transfer machines in addition to these parts. The crucial factors for compatibility are the size of the part, the scope of machining and the quantity. Please contact us – we will be happy to work with you to test the use of our machines for your specific requirements.

Your point of contact

Mario Köhler

sales@variomatic.de

+49 371 84246-27